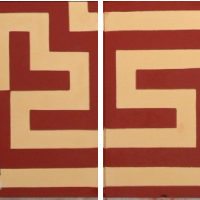

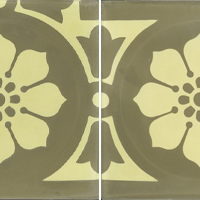

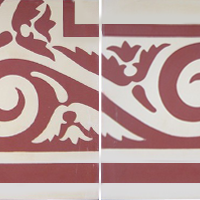

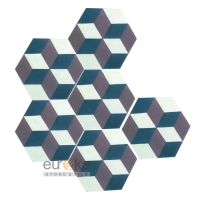

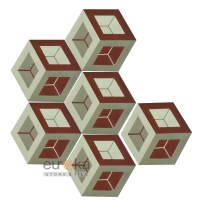

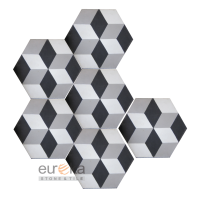

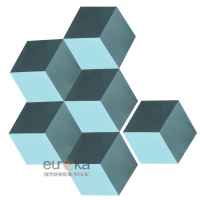

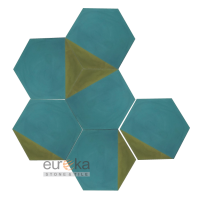

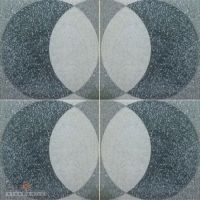

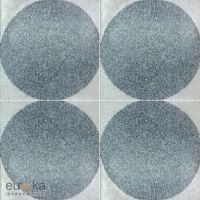

ENCAUSTIC HANDMADE CEMENT TILES

The installation process is very simple and rapid to accomplish. However, great care should be taken so as not to damage tile surfaces and edges during installation process.

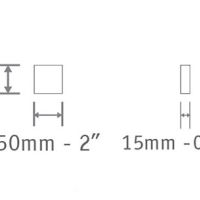

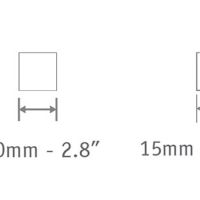

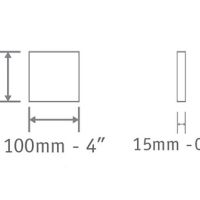

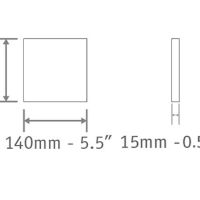

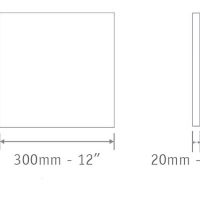

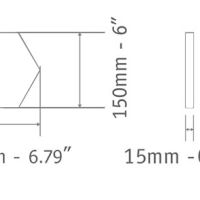

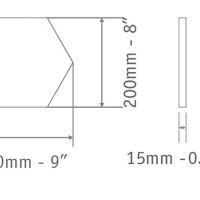

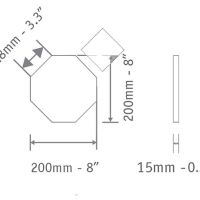

a) The tiles should be laid on perfect flat surfaces. Leave a joint of 1-2mm between tiles in installation. After you prepare the concrete cover, the tiles retain almost 2cm height altogether.

b) The tiles can be installed by using either glue/adhesive or thin mortar layer bed. To have a good adherence of floors:

• Submerge tiles in a water basin before the installation

• It is necessary to trowel glue or mortar on both surface of leveled surface and at back of tiles by using a toothed paint scraper

c) Laying tiles must be carefully handled to avoid of chipping out on edges. After laying the tiles, level tiles on floors by hands or rubber hammer and construction ruler.

d) The exceeding adhesive cement on tile surfaces or edges has to be immediately cleaned on the surface with humid cloths. Otherwise such kind of stains will be very difficult to be removed later on.

e) Leave the floors untouched and protected until the mortar to be dried naturally enough before grouting.

f) Fulfill the joints by grouting liquid. Color of this liquid should be white for the most suitable in any case. Other colors can be used on owner preference. Remove all excessive grouting materials before it is dried.

g) Wash the floors with soap and clean water and leave floors dried completely, then apply suitable penetrating sealer from qualified manufacturers to have the most expecting floor finishes. It is strongly suggested to test sealer with one single tile before apply the whole floor.

h) Depending on traffic frequency, repeat this sealing process every 6-12 months.

Tip

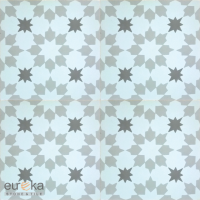

• Encaustic cement tile is handmade product and made from natural materials so the tiles are subject to contain color variations. It is necessary to check tiles randomly before installation to have better distribution of tiles between laying areas to achieve the most uniform floors.

• There will be some calcareous spots on tile surfaces as character of cement tiles to be naturally caused by reaction between chemical factors in cement and water. Those spots will be disappeared automatically from 1 to 2 months afterward of using

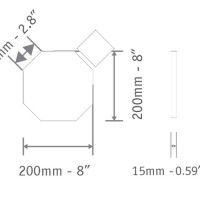

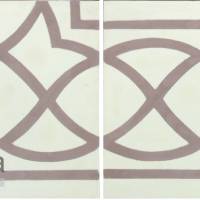

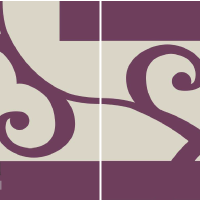

• Don’t leave any space among the squares. Adjust the squares to form the design well .

• A good leveling of your ground will facilitate its polishing.

Cement tiles are said to be appeared since 19th century in Spain and very soon, they were exhibited in France. Right after that, they became very popular in Europe, then America and were considered a high-end floor covering later on. They had been used in thousands of landmark public buildings and palaces around the world. Cement tiles are made by hands, one at a time, using mineral pigments, cement, a mold and a hydraulic press machine; Colorful patterns of cement tiles can be customized; They are expected to have slight imperfections which give them character and depth…All of those aspects have made cement tiles special luxury building material. Nowadays, they are known throughtout worldwide as “Encaustic Handmade cement tile” and used in either interior or exterior areas.

Very soon right after being found, In 1858, French came to Vietnam, they also brought techniques and equipments to produce cement tiles to Vietnam. Being handmade products, labors play the most important factor of this production while Vietnamese people are always acknowledged clever, skilled and hardworking. Therefore, Encaustic Handmade Cement Tiles could be known as the tradition of Vietnam. People can easily find in Vietnam many hundred-year houses or buildings or palaces, villas… with floors remaining luxury beauties such as Hochiminh Post office, Saigon Notre-Dame Cathedral..

EUREKA is now considered the Biggest producer of Encaustic Handmade Cement Tiles in Vietnam with total capacity of 18-22 containers per month. EUREKA has exported this beautiful product to over 45 different Countries in all 5 Continental.